Customer Satisfaction

Perfect reproduction of the formulation based on specifications provided by customers with different properties, viscosities, and surface tensions to suit their needs.

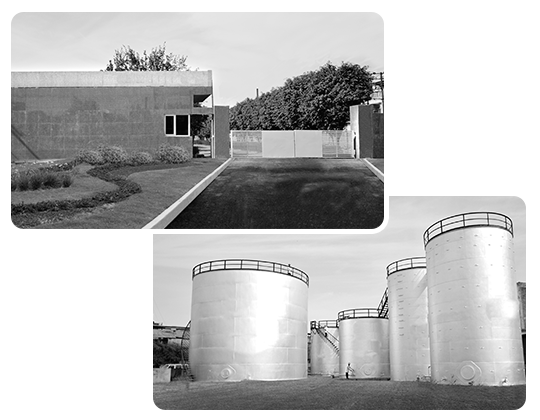

Suitable Infrastructure

Our in-house R&D laboratory is the only one of its kind in the country fully equipped with the latest and most advanced testing equipment as per ASTM standards.

Leading Brand Approvals

We are approved OEM for leading brands such as Hindustan Motors, Mitsubishi, ACE, Atul Auto among others

One Stop Solution

We are the 7th largest captive capacity plant available at a single location with a capacity of 1,44,000 KI Capacity Of Per Annum

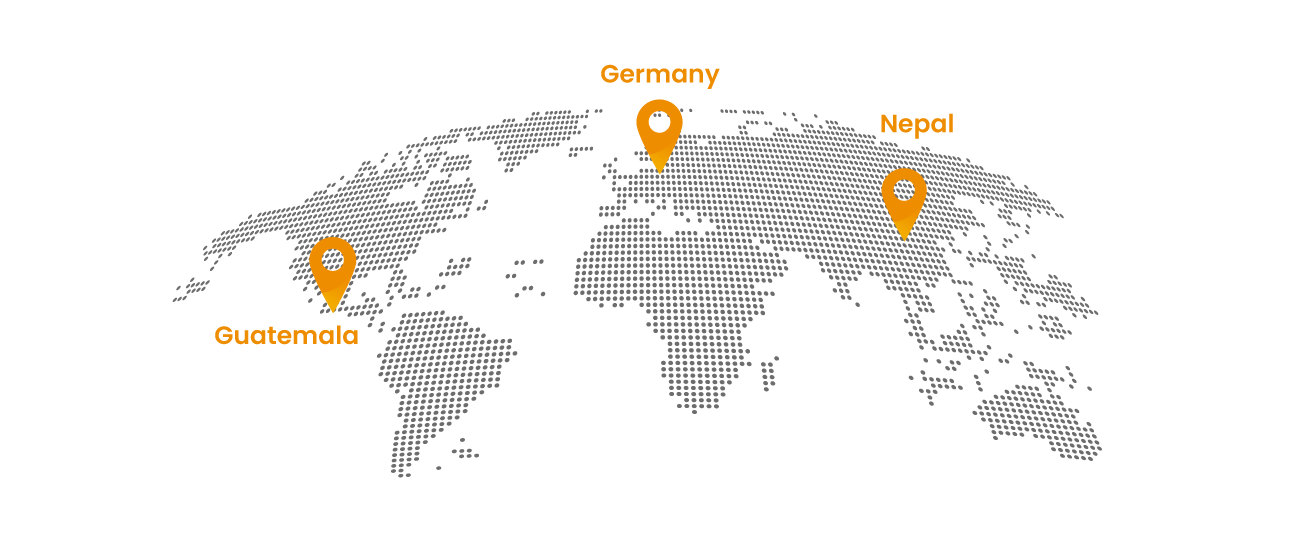

Raaj Industrial Lubricants Limited, established in the year, 1990 by the Rajgarhia Group Of Enterprises, has diversified interests spanning across Automobiles, Pharmaceuticals, Steel, Abrasives, Refractories etc. The plant spreads over a 10-acre campus in the Faridabad Industrial Area, comprising twin petroleum blending plants, dedicated to the domestic market and international trade.

Our lubricating oil not only provides maximum protection against friction and wear on demanding surfaces but also helps maintain the integrity of your components.

We offer a range of lithium-based all-purpose greases with excellent water-resistant capability and provide you with a smooth performance.

An economical, high-performance aqueous coolant concentrate that can be used at a recommended dilution to get the high-level frost and corrosion protection

Highly refined mineral oil with a low zinc-containing anti-wear additive system to provide outstanding anti-wear and thermal stability performance.

At Raaj Industrial Lubricants Ltd., the belief in research and development (R&D) as a safeguard for a stable future is unwavering. The Research department, led by a dedicated team of professionals from IIT Delhi, has invested over 0.5 million dollars solely in research equipment. In parallel, the team actively works on enhancing the existing product line to optimize costs and ensure maximum quality.

The company has achieved notable breakthroughs in the industry through the development of cutting-edge technologies. For instance, OIL-DETAC, a fluorescence UV light detection system for OEMs, and LUBISTRANDS, an anti-gravity technology created in-house at our R&D center, stand as remarkable achievements.

Presently, our focus lies on the advancement of next-generation automobiles, encompassing EVs, Hydrogen cell Automobiles, and flex engines. We strive to cater to the specific fluid requirements of these vehicles, ensuring that our products align perfectly with their needs.

of our significant accomplishments is the successful creation of G-48 H.O.A.T cooling system fluids for EV vehicles. These fluids possess specifications and performance on par with the currently used systems, establishing them as the most advanced EV fluids available in the market today.

An In-house storage capacity of 3000MT for base oils & a leased out capacity of over 1000MT at Mumbai Port.

The blending system is a patented air purging technology which gives a homogenous product, consumes 20% less energy, cycle time is 30% less with no T-M-B bias.

An In-house storage capacity of 3000MT for base oils & a leased out capacity of over 1000MT at Mumbai Port.

Automatic precision filling lines from 210L barrels to 6 head and 4 head automatic small pack filling lines

The blending system is a patented air purging technology which gives a homogenous product, consumes 20% less energy, cycle time is 30% less and there is no T-M-B bias.

The QA/QC team constantly works on product formulations keeping both package and component based to give the optimal cost of product with enhanced product performance

All departments including QA/QC are controlled on an ERP platform which ensure fast turn-around time, complete process transparency and traceability and eliminate any procedural lapses

In- house fully equipped lab as per the latest ASTM standards helps us deliver futuristic products & technologies to this ever changing and evolving industry.

With a team of industry experts and specialists, use of Advanced Technologies & Systems we ensure that your vehicle is well-oiled for increased performance and protection against wear.

To make sure we are never out of date, we have conveniently-located, state-of-the-art laboratories where we conduct advanced testing in a wide range of areas.

We have had the privilege of working with some of the biggest names in the industry including SERVO, Mobil, Total among many others.

With our state-of-the-art production process and cutting edge quality control systems, each RULL product is an epitome of uncompromising quality.

Since switching to Raaj Oils' automotive lubricating oils, we have noticed a significant improvement in the performance and longevity of our plant machinery. The oils provide excellent protection against friction and wear, ensuring the integrity of our components. We are highly satisfied with the quality and reliability of Raaj Oils.

The automotive grease from Raaj Oils has been a game-changer for our lubricants brand. It offers exceptional water-resistant capability and delivers a smooth performance. We are now adding more lubricants to our range & getting it all done from Madhav & his team.

We have been associated with Raaj Oils' automotive coolants for our private label brand since the last 3 years, and we are extremely pleased with the results. The coolant concentrate provides excellent frost and corrosion protection, even at high dilutions. It has proven to be both cost-effective and high-performing. Our customers love the product.

As an industrial plant manager, I rely on high-quality oils to keep our machinery running smoothly. Their highly refined mineral oil, combined with the low zinc-containing anti-wear additive system, ensures outstanding anti-wear and thermal stability performance. We’ll continue procuring from Raaj Oils.

As a supplier of automotive components, we understand the importance of partnering with reliable and high-quality lubricant providers. Raaj Oils has been an invaluable partner in meeting our lubrication requirements. Their automotive lubricating oils have consistently delivered outstanding performance, protecting our components against wear and extending their lifespan.